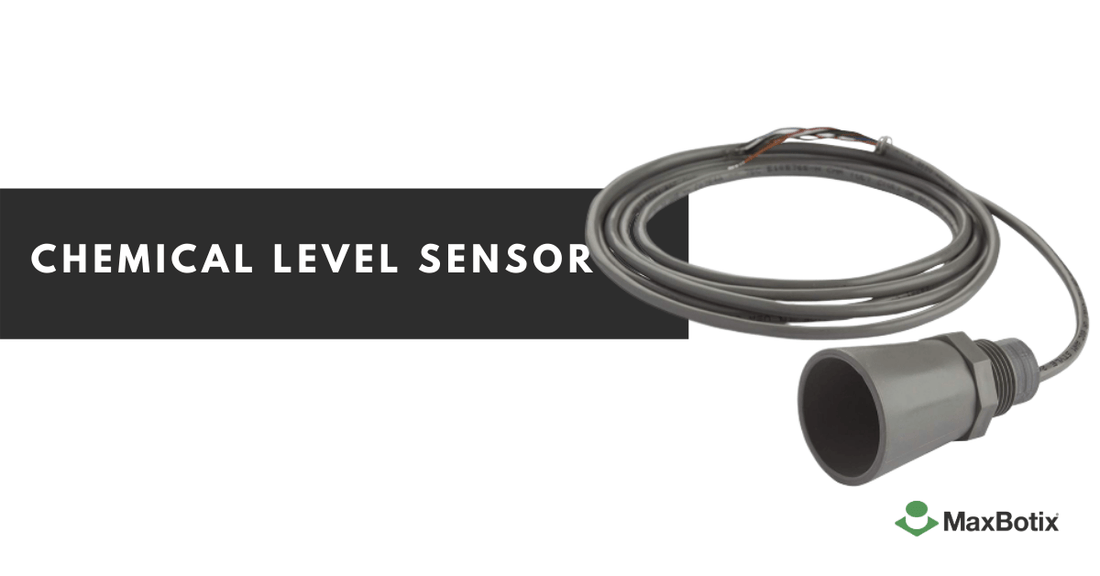

Chemicals can be corrosive and affect the use of your sensor in a tank or other environment where chemicals are present. For that, we can offer a non-contact liquid level sensor, which acts as a non-contact, continuous level sensor.

Chemicals can be corrosive and affect the use of your sensor in a tank or other environment where chemicals are present. For that, we can offer a non-contact liquid level sensor, which acts as a non-contact, continuous level sensor.

View our Weather Resistant, IP67 rated Sensors here.

The management of the liquid level of chemicals can be challenging for the manufacturing industry. In these industries, containers to house the chemicals can range from very large mixing vats to smaller tanks.

Best Practices for Chemical Level Measurement

The ultrasonic level sensor you install must have a clear view of the liquid surface. There should be no obstructions such as walls of the tank or any fittings. The sensor has to be located above the highest level of liquid and never submerged. This is crucial for accurate ultrasonic liquid level measurement.

Additional Sensor Mounting Notes

Additional Sensor Mounting Notes

For tanks that are outdoors, they will likely be influenced by the weather. The heat and cold may result in the fluctuations of range readings. For that, we offer temperature compensation on some versions of our sensors. For best results with temperature compensation, the sensor should not be mounted in direct sunlight as this can sway the temperature reading higher than the actual temperature. This enhances the reliability of ultrasonic sensor for liquid level measurement in varying conditions.

What material(s) will be in the sensor environment? In our chemical compatibility guide, we’ve detailed the ideal chemical environments that our sensors have been used successfully. We also list those where our sensors are not compatible with that particular use.  We have developed the F-Option for additional protection necessary in a few hazardous chemical environments.

We have developed the F-Option for additional protection necessary in a few hazardous chemical environments.

- Diesel

- Chlorobenzene(Mono)

- Gasoline

- Hydrofluoric acid*

- Hydrochloric acid

- Sewers

Note: Our Wire Attach Option is ideal for applications where the pin-out needs to be fully protected and sealed. This is also an alternative to soldering the wires yourself.

Collaborator/ Case Studies: Sensors Used in Chemical Environments

Collaborator/ Case Studies: Sensors Used in Chemical Environments

Invigicom - Tank Level Sensor

Florida based company Invigicom Inc. developed an easy to use solution that replaces traditional monitoring systems that use float gauges or pressure sensors. This showcases an effective ultrasonic level sensor application.

Why use this solution?:

- Easy to use solution for wireless tank level monitoring

- Get email alerts for tank servicing.

- Invigicom monitors the back office for system problems. In many cases, they will see problems before the customer does and have the ability to fix them through the back office.

Radio Bridge Inc. - Long-range wireless IoT Sensor designer and manufacturer Radio Bridge Inc. provides a general-purpose LoRaWAN bridge using MaxBotix sensors to be used in many applications. Summary:

Radio Bridge Inc. - Long-range wireless IoT Sensor designer and manufacturer Radio Bridge Inc. provides a general-purpose LoRaWAN bridge using MaxBotix sensors to be used in many applications. Summary:

- Industries served: retail, industrial, oil and gas, deduction, utilities, security

- Typically used in tank monitoring applications

- Wireless connectivity with LoRaWAN protocol

- Wireless penetration through structures such as walls and floors

Not sure if our sensors would be the right fit for your application?

Click the button below to contact our team to discuss your project needs.