Ultrasonic Level Sensors

For Product Developers and Engineers

How Ultrasonic Level Sensors Work

Ultrasonic sensors work by sending out a sound wave at a frequency above the range of human hearing. The transducer of the sensor acts as a microphone to receive and transmitter to send the ultrasonic sound.

Our ultrasonic sensors, like many others, use a single transducer to send a pulse and to receive the echo. The sensor determines the distance to a target by measuring time lapses between the sending and receiving of the ultrasonic pulse.

Common uses include:

- Level

- Flow

- Monitoring Flow

Our ultrasonic level sensors are easy to install and low maintenance. They are intended for non-contact level sensing, which means there will be a lack of build up on the sensor face itself. The level sensors are required to have an unhindered path to the surface you want to detect.

-

MB7850 XL-TankSensor-WRMA

Our newest High Performance Tank Level Sensor!

Thousands of applications supported

- Our sensors are tested to last 20+ years (MTBF)

- We warranty our sensor from a manufacturing defect

We Care About Your Success!

We’ve helped over 20,000 engineers find sensor solutions for their applications.

Our sensors have been integrated into over 10,000 projects.

Chemical Compatibility

The choice to use ultrasonic sensors in an application can potentially depend on the compatibility with certain chemical environments.

To ensure the reliability of using these sensors, it’s important to understand what chemicals they are designed to work with so you can accurately measure your targets in chemical tanks.

When selecting an ultrasonic sensor for your application, it’s important to know the following about the chemical environment where the sensor will be used:

- Is it corrosive?

- Does it contain solvents or other chemicals that might affect the operation of the sensor?

You can review our chemical compatibility chart here for more details.

As you’re searching for the level sensor for your application. You’ll find that you need to select a sensor that best suits your needs for your project.

With that being said, our sensors operate well in different level sensing applications.

Measure Levels With a Reliable Supplier!

Ultrasonic Level Sensor For Tanks

If mounting in a tank, our sensors do offer a narrow beam pattern, reducing the chance the sensor will detect the wall of the tank.

If the tank has smooth walls on the inside, our MB7850 sensor contain our Most-likely and stability filtering. This will let the sensors choose the target that gives the largest acoustic return. This will generally be the liquid level inside of the tank.

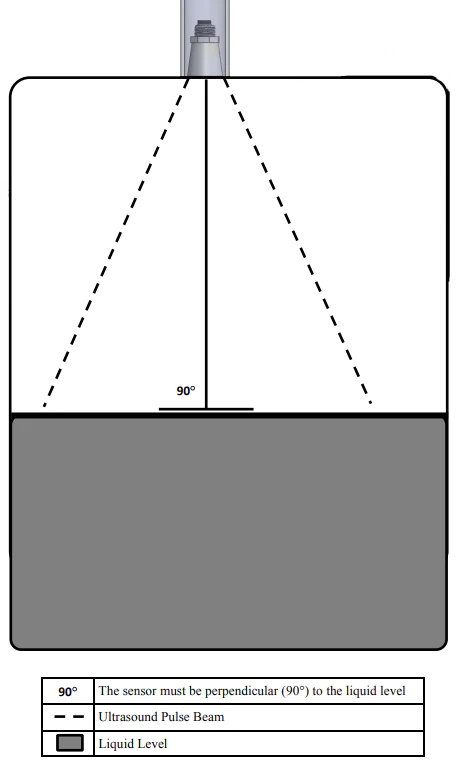

The image below shows the ideal mounting of the sensor in a tank.