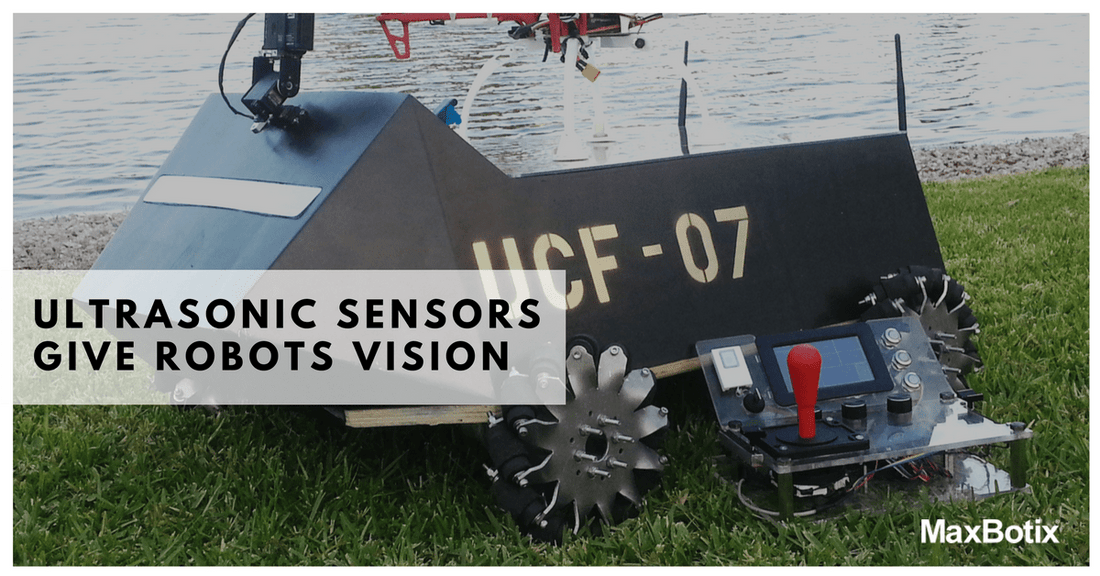

A robot without an ultrasonic sensor is blind. Ultrasonic sensors allow our robots to react to the world around them like we do with our eyes and ears. There are many types of ultrasonic sensors, and they provide your robot with new or improved senses. At MaxBotix Inc., we know how to best leverage ultrasonic sensors for their performance. The ultrasonic sensor provides a great set of eyes for your robot’s autonomous navigation. Our ultrasonic sensors provide fast response times which allow your robot to respond quickly to the changing environments around it. Our ultrasonic sensors provide your robots with valuable information on the distance and direction to the target, for more information we recommend the following article: MaxBotix Ultrasonic Sensors Find Direction and Distance. MaxBotix Inc., provides easy-to-use ultrasonic sensors that only require three wires for connection in many applications: power, ground, and one output. The ultrasonic sensors are also configured to allow you to easily add in more sensors for better coverage depending on the needs of your robot sensor. You can learn more on using more than one ultrasonic sensor by reading the following article: Using Multiple MaxSonar Ultrasonic Sensors. Our ultrasonic sensors for robots interface over many communication protocols such as RS232, Pulse Width, Analog Voltage, TTL, and I2C. To learn more about this, we invite you to read Ultrasonic Sensor Output Options. You may also want to check out using an ultrasonic sensor to detect and avoid walls to help you get started.

A robot without an ultrasonic sensor is blind. Ultrasonic sensors allow our robots to react to the world around them like we do with our eyes and ears. There are many types of ultrasonic sensors, and they provide your robot with new or improved senses. At MaxBotix Inc., we know how to best leverage ultrasonic sensors for their performance. The ultrasonic sensor provides a great set of eyes for your robot’s autonomous navigation. Our ultrasonic sensors provide fast response times which allow your robot to respond quickly to the changing environments around it. Our ultrasonic sensors provide your robots with valuable information on the distance and direction to the target, for more information we recommend the following article: MaxBotix Ultrasonic Sensors Find Direction and Distance. MaxBotix Inc., provides easy-to-use ultrasonic sensors that only require three wires for connection in many applications: power, ground, and one output. The ultrasonic sensors are also configured to allow you to easily add in more sensors for better coverage depending on the needs of your robot sensor. You can learn more on using more than one ultrasonic sensor by reading the following article: Using Multiple MaxSonar Ultrasonic Sensors. Our ultrasonic sensors for robots interface over many communication protocols such as RS232, Pulse Width, Analog Voltage, TTL, and I2C. To learn more about this, we invite you to read Ultrasonic Sensor Output Options. You may also want to check out using an ultrasonic sensor to detect and avoid walls to help you get started.

Zumo Avoiding Robot arduino and EZ0 MaxSonar

Get Started with Ultrasonic Sensors

To get started using an ultrasonic sensor, you can check out the ultrasonic sensors below to help you build the ultimate robot. They're fast, accurate, low-cost, and easy-to-use. High Performance Ultrasonic Sensor - XL-MaxSonar®-EZ™. The industrial XL‑MaxSonar‑EZ sensors are high-performance ultrasonic sensors with high power output, noise rejection, auto calibration, and factory calibrated beam patterns. The XL‑MaxSonar‑EZ sensors have three outputs: analog voltage, serial, & pulse width. Advanced users are encouraged to view the XL‑MaxSonar‑AE sensors which feature analog voltage, serial, & a real‑time analog envelope waveform outputs. To view all the products in the XL-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - XL-MaxSonar®-EZ™. The industrial XL‑MaxSonar‑EZ sensors are high-performance ultrasonic sensors with high power output, noise rejection, auto calibration, and factory calibrated beam patterns. The XL‑MaxSonar‑EZ sensors have three outputs: analog voltage, serial, & pulse width. Advanced users are encouraged to view the XL‑MaxSonar‑AE sensors which feature analog voltage, serial, & a real‑time analog envelope waveform outputs. To view all the products in the XL-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - HRLV-MaxSonar-EZ. The high-resolution HRLV‑MaxSonar‑EZ sensors are high-performance ultrasonic sensors with noise rejection, improved automatic calibration, and factory calibrated beam patterns. The HRLV‑MaxSonar‑EZ sensors have three outputs: Analog Voltage, Pulse Width, RS232 or TTL serial data. The HRLV‑MaxSonar‑EZ products are high-resolution ultrasonic sensors, that provide a component module solution that offers easy to use outputs, no sensor dead zone, calibrated beam patterns, stable range readings, low power demands, and a host of other features detailed in the product datasheets. To view all the products in the HRLV-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - HRLV-MaxSonar-EZ. The high-resolution HRLV‑MaxSonar‑EZ sensors are high-performance ultrasonic sensors with noise rejection, improved automatic calibration, and factory calibrated beam patterns. The HRLV‑MaxSonar‑EZ sensors have three outputs: Analog Voltage, Pulse Width, RS232 or TTL serial data. The HRLV‑MaxSonar‑EZ products are high-resolution ultrasonic sensors, that provide a component module solution that offers easy to use outputs, no sensor dead zone, calibrated beam patterns, stable range readings, low power demands, and a host of other features detailed in the product datasheets. To view all the products in the HRLV-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - HRUSB-MaxSonar®-EZ™. The HRUSB-MaxSonar-EZ ultrasonic sensors feature an easy to use USB interface that connects directly to a computer with a standard Micro-B USB cable. The HRUSB‑MaxSonar‑EZ sensors detect objects in a calibrated detection zone and report when an object (such as a person) enters the detection zone. The target is released after leaving the HRUSB‑MaxSonar‑EZ detection zone. The HRUSB‑MaxSonar‑EZ ultrasonic sensor provides a component module solution that offers easy integration with USB connectivity, no sensor dead zone, calibrated beam patterns, stable range readings, and a host of other features. To view all the products in the HRUSB-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - HRUSB-MaxSonar®-EZ™. The HRUSB-MaxSonar-EZ ultrasonic sensors feature an easy to use USB interface that connects directly to a computer with a standard Micro-B USB cable. The HRUSB‑MaxSonar‑EZ sensors detect objects in a calibrated detection zone and report when an object (such as a person) enters the detection zone. The target is released after leaving the HRUSB‑MaxSonar‑EZ detection zone. The HRUSB‑MaxSonar‑EZ ultrasonic sensor provides a component module solution that offers easy integration with USB connectivity, no sensor dead zone, calibrated beam patterns, stable range readings, and a host of other features. To view all the products in the HRUSB-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - LV-MaxSonar®-EZ™. The original LV‑MaxSonar‑EZ products were the first low-cost ultrasonic distance sensors to provide a component module solution that offered easy to use outputs, no sensor dead zone, calibrated beam patterns, stable range readings, low power demands, and a host of other features detailed in the product datasheets. As a result, our component modules have found a wide acceptance in the robotics community, and have also been integrated into a number of industrial solutions including: proximity sensors for store displays, high-speed sensors for vending machines, remote monitoring sensors for parking monitors, and distance sensors used to evaluate people's height. To view all the products in the LV-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - LV-MaxSonar®-EZ™. The original LV‑MaxSonar‑EZ products were the first low-cost ultrasonic distance sensors to provide a component module solution that offered easy to use outputs, no sensor dead zone, calibrated beam patterns, stable range readings, low power demands, and a host of other features detailed in the product datasheets. As a result, our component modules have found a wide acceptance in the robotics community, and have also been integrated into a number of industrial solutions including: proximity sensors for store displays, high-speed sensors for vending machines, remote monitoring sensors for parking monitors, and distance sensors used to evaluate people's height. To view all the products in the LV-MaxSonar-EZ Sensors Product line click here.

High Performance Ultrasonic Sensor - XL-MaxSonar®-WR™. The industrial outdoor XL‑MaxSonar‑WR sensors have a robust PVC housing designed to meet IP67 water intrusion. The sensors provide short to long distance detection and ranging with a narrow beam pattern. The XL‑MaxSonar‑WR outdoor ultrasonic sensors have high power output, noise rejection, auto calibration, and factory calibrated beam patterns. Users should select a sensor with their outputs of choice and reading filtering that matches their application. Models are available with analog voltage output, serial digital output, pulse width output (select models), & real-time analog envelope output (select models). To view all the products in the XL-MaxSonar-WR Sensors Product line click here.

High Performance Ultrasonic Sensor - XL-MaxSonar®-WR™. The industrial outdoor XL‑MaxSonar‑WR sensors have a robust PVC housing designed to meet IP67 water intrusion. The sensors provide short to long distance detection and ranging with a narrow beam pattern. The XL‑MaxSonar‑WR outdoor ultrasonic sensors have high power output, noise rejection, auto calibration, and factory calibrated beam patterns. Users should select a sensor with their outputs of choice and reading filtering that matches their application. Models are available with analog voltage output, serial digital output, pulse width output (select models), & real-time analog envelope output (select models). To view all the products in the XL-MaxSonar-WR Sensors Product line click here.

High Performance Ultrasonic Sensor - HRXL‑MaxSonar®‑WR™. The industrial high resolution outdoor HRXL-MaxSonar-WR sensors have a robust PVC housing designed to meet IP67 water intrusion. The sensors provide short to long distance detection and ranging with a narrow beam pattern. The HRXL-MaxSonar-WR outdoor ultrasonic sensors have high power output, noise rejection, auto calibration, temperature compensation, and factory calibrated beam patterns. Users should select a sensor with their outputs of choice and that matches their application. Models are available with analog voltage output, RS232 Serial output (select models) or TTL Serial output (select models), and pulse width output. To view all the products in the HRXL-MaxSonar-WR Sensors Product line click here. Once you have your ultrasonic sensor, you can start testing by using our Quick Start Guide.

High Performance Ultrasonic Sensor - HRXL‑MaxSonar®‑WR™. The industrial high resolution outdoor HRXL-MaxSonar-WR sensors have a robust PVC housing designed to meet IP67 water intrusion. The sensors provide short to long distance detection and ranging with a narrow beam pattern. The HRXL-MaxSonar-WR outdoor ultrasonic sensors have high power output, noise rejection, auto calibration, temperature compensation, and factory calibrated beam patterns. Users should select a sensor with their outputs of choice and that matches their application. Models are available with analog voltage output, RS232 Serial output (select models) or TTL Serial output (select models), and pulse width output. To view all the products in the HRXL-MaxSonar-WR Sensors Product line click here. Once you have your ultrasonic sensor, you can start testing by using our Quick Start Guide.

Understanding Ultrasonic Sensors in Robotics

Ultrasonic sensors function by emitting high-frequency sound waves and detecting their reflections from nearby objects. This method allows them to accurately detect and determine the distance and position of objects, making them invaluable in robotics for feature extraction techniques and recognizing solid objects.

When used in robotic systems, ultrasonic sensors provide a reliable alternative or complement to light sensors and proximity sensors. Unlike visual systems, these sensors are not affected by lighting conditions or the transparency of objects, making them ideal for a variety of environments.

The Edge of Ultrasonic Sensor Arrays in Robotics

Ultrasonic sensor arrays take the capabilities of single sensors to the next level. By combining visual information from multiple ultrasonic sensors, these arrays can create a more comprehensive ‘view’ of the robot’s surroundings. This enhanced perception is crucial for complex tasks where understanding the environment in three dimensions is essential.

The use of ultrasonic sensor arrays in robotics is a game-changer, especially when it comes to navigating unpredictable or cluttered environments. These sensors work collaboratively to map out space, identifying obstacles with precision. This capability is particularly beneficial in industrial settings where safety and accuracy are paramount.

How Ultrasonic Sensors Empower Robots

Using ultrasonic sensors, robots gain the ability to perform tasks with a level of precision that was previously unattainable. These sensors allow robots to engage in intricate operations, such as sorting, assembling, and inspecting products. The technology behind these sensors involves intricate feature extraction object recognition techniques, enabling robots to distinguish between different types of objects and their spatial orientation.

One of the most significant advantages of using ultrasonic sensors in robots is their ability to function in diverse environments. Whether it’s in bright sunlight or complete darkness, these ultrasonic sensors work to maintain their accuracy, making them more reliable than many traditional vision systems in challenging conditions.

Innovations and Applications of Ultrasonic Sensors in Robotics

Innovations in ultrasonic sensor technology have broadened their applications in robotics. Robots equipped with these sensors are now capable of more delicate and sophisticated tasks. For instance, in medical robotics, ultrasonic sensors are used for precise movements during surgeries or diagnostics, ensuring safety and accuracy.

In the realm of industrial automation, ultrasonic sensors are crucial for tasks that require fine detail and precision. From quality control in manufacturing lines to inventory management edge tracking in logistics, these sensors provide robots with the necessary ‘vision’ to perform tasks effectively and efficiently.

Overcoming Challenges with Ultrasonic Sensors

Despite their many advantages, integrating ultrasonic sensors into robotic systems poses certain challenges. However, advancements in ultrasonic sensor arrays and signal processing techniques have significantly mitigated these issues. Modern sensors are more adept at filtering out noise and interference, allowing for more accurate readings and dependable operation in complex industrial environments.

MaxBotix’s expertise in this field ensures that the ultrasonic sensors you integrate into your robots are not just cutting-edge but also tailored to meet the specific demands of your operations.

The Future of Ultrasonic Sensors in Robotics

The future of ultrasonic sensors in robotics looks promising, with ongoing research and development paving the way for even more innovative robot applications. As these sensors become more sophisticated, their integration into robotics will enhance the capabilities of robots, making them more autonomous and adaptable to a range of tasks and environments.

Reaping the Benefits of Ultrasonic Sensors in Robotics

Ultrasonic sensors have revolutionized how robots perceive and interact with their environment. These sensors provide a reliable, efficient means for robots to ‘see’, making them indispensable in modern industrial operations.

When it comes to sourcing high-quality, reliable ultrasonic sensors for your robotics needs, MaxBotix stands as a beacon of innovation and reliability in the field of robotic applications. Their expertise and range of products ensure that your robotics systems are equipped with the best tools to succeed.

Contact our team today to explore how MaxBotix can elevate your robotic systems with advanced ultrasonic sensors and data, ensuring that your operations are at the forefront of technological innovation.