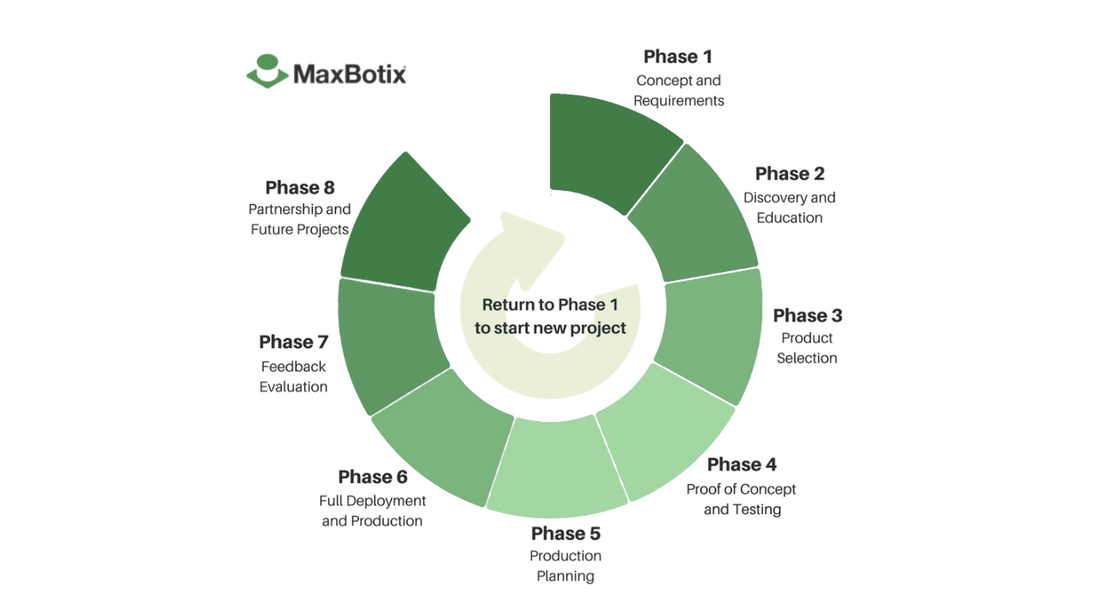

This guide outlines the process of working with MaxBotix from concept to product design, testing, and deployment and full production. The guide gives you valuable information and Design Tips to help you complete a successful ultrasonic sensor implementation.

Phase 1: Concept & Requirements

We start the process by developing a mutual understanding of your application, vision, specific requirements, and sensor needs. This step defines the details and outcomes you require to be successful.

This includes reviewing your sensor, application, and production requirements. Additionally, we explore your use of a contract manufacturer (CM) to ensure there is a smooth transition into high volume production. This step is typically completed by a phone call. At the end of this step, we complete an initial evaluation to determine if we can meet your sensor and application needs.

Determining that an Ultrasonic Sensor is the Right Solution

The integration process starts by defining how the ultrasonic sensor solution will make your design a success. The easiest way to define this is with the following three questions:

1. What is the application vision and how does a sensor help accomplish this?

This is the most critical question because you must select a sensor that matches your application. The following are a few examples that will help you critically think about the end results of a successful integration:

- The sensor must report the distance to your target with 1mm resolution.

- The sensor must trigger your system at a certain distance after the object is detected.

- The sensor must detect people out to this distance and trigger your system.

DESIGN TIP Initial concept and design is the right time to determine if you need an indoor (protected) or an outdoor (non-protected) environment sensor. A protected environment essentially means that the sensor will not get wet. A non-protected environment means that the sensor can be wet, dusty and exposed to weather. You can view our article on this topic on our website.

2. What are the mandatory specific requirements or features that an ultrasonic sensor must possess for the integration to be successful?

This may include specifications such as 1mm resolution, 5-volt power supply, 7-meter object detection, etc.

3. What are the optional requirements that will make the implementation better, but are not showstoppers to moving forward?

Review the list created in step 2 from the mandatory specific requirements or features and verify each one is required and not optional. If there are any specifications in this list that are not showstoppers, move them to the optional list.

Researching Previous Sensor Use

It is critical that the end performance is clearly defined to make the design successful. It is important to take time to research the history of the particular use of ultrasonic sensors for your application. Researching your application is where you will learn the most about how to integrate the sensor to achieve the best result without having to reinvent the wheel. We understand that you may have done the research, so feel free to skim this section.

First, you must determine if ultrasonic sensor technology has been used for your type of application successfully in the past. It is far better to stop the process on an idea that has been proven unsuccessful than to spend your time and resources to get the same result. If you find yourself not sure where to start, our friendly sales team will be glad to assist you to leverage our history to help you through this process.

DESIGN TIP Will you use more than one sensor in the same environment? Check out this link that talks about ultrasonic multi-sensor operation. Unlike previously believed, it is possible to run multiple ultrasonic sensors in the same environment and get great results. It is only a matter of selecting the right sensor for the job. MaxBotix has several options listed in this article that will help you succeed on your project design.

Project Schedule & Manufacturing Requirements

Now that you have determined that ultrasonic sensors are feasible solutions for your application, it is time to review other critical application requirements. We start by looking at your desired production requirements and timeline to help set your project guidelines. We collaborate on how we can best deliver the results that you need to be successful. We find it is critical to understand your timeline to ensure smooth production operations and delivery of products.

We look at your needs and evaluate our capacities. Shipping tens of thousands of sensors a week is quite common. Additionally, our scalable manufacturing processes allow for rapid expansion to meet growing production demands.

We also explore your use of a CM to ensure there is a smooth transition into high volume production. Experience shows that it is important to get your CM involved early to make sure they are ready to place your orders without delay. This ensures your entire production team is on the same page.

Phase 2: Discovery & Education

During this phase, we share information about our mutual businesses and goals. We present our process for doing business. Additionally, we review and discuss any legal requirements such as contracts, NDAs, and tax exemption certificates. If an NDA has not been executed at this point, we execute a mutual NDA. Assuming all things check out, we move onto the next phase, Product Selection.

Phase 2 helps us verify our business practices fit together. In this phase, four specific areas of business are covered:

- Your business and its processes

- The MaxBotix way of doing business

- Non‑Disclosure (NDA) agreements

- Any relevant contracts or statements of work

Your Business

The way you do business is likely one of the reasons for your success. We recognize that it is very important for MaxBotix to understand your business to secure a successful B2B relationship. We want to know and understand your needs. For example:

- Your ability to quickly deliver manufactured orders

- Your team’s expertise at solving complex problems with innovative solutions

- Marketing acumen for products in a certain sector

The more we know who you are and what makes you successful, the better we can collaborate on your projects. Additionally, we learn about how you conduct your business with other business partners. We accomplish this by asking you a few simple questions.

- What are your expectations of an ideal vendor?

- How do you typically work with different vendor processes?

- What are some of the challenges that you have faced with other vendors?

Learning how you schedule and place orders is our next goal.

- How does this process work for your company?

- How long does it take?

- Who is our contact for design, engineering, testing, and order fulfillment?

MaxBotix Inc.

After we understand how you do business, we give you with a brief overview of MaxBotix Inc. We want you to have a complete representation of us including our values, vision, and culture, as well as our products and services. We also want to share with you a few of the advantages of working with MaxBotix. Experience shows that B2B relationships benefit more with solid education and discovery.

Part of our Design Cycle process includes creating a positive and meaningful experience for you. Our mission is to be the sensor company of first choice by providing high quality, easy‑to‑use, competitively priced sensors that meet customer requirements. You can view our Company Profile for more information.

MaxBotix offers a number of products and services to help you be successful. These include:

- Over 200 standard application‑specific sensors

- Semi‑custom versions of these sensors

- Value‑added options and accessories

- New sensor development services

- Final product engineering assessment services

- Turn-key product manufacturing

Now that you have an understanding of how we do business, we want to share some advantages of doing business with MaxBotix Inc:

- Secure and reliable supply chain: As a start‑to‑finish manufacturing company, we understand the need for exceptional products. We choose to do business with vendors that provide us with quality products and services so you can rely on us for your sensor needs.

- Sensors matched to customer applications: Application‑specific sensors result in trusted sensor performance. This allows you to select many of your sensor specifications, from resolution to sensitivity.

- Products that stand the test of time: Our high MTBF of 200,000+ hours shows that our products last. You can read more in our article: MaxSonar Reliability Demonstration.

- High volume and scalable production: We easily support deliveries of over 10,000 units per week.

- Friendly sales and tech support staff: We are eager to collaborate with you throughout the Design Cycle.

- Payment terms: Prepayment benefits our customers because you save money. MaxBotix eliminates the additional costs and risks of payment tracking, delayed payments, late payments, or non‑payment into the pricing structure.

- Large volume scheduled orders: We accept purchase orders for up to one year with scheduled deliveries. This gives you the best per part pricing on your sensors. Ask your sales rep for complete details.

- Factory calibration and testing: You receive consistent part‑to‑part operation even years after your first purchase.

- Customization: We offer custom and semi‑custom sensors to meet your exact needs.

Non‑Disclosure Agreements (NDA) & Other Contracts

As a business, we understand your need to protect your competitive advantage and proprietary information. We also know that sometimes to achieve success for a project, some information may have to be shared with us. As a result, we have an NDA process which assures you of confidentiality as we gain a thorough understanding of your application so we can collaborate to meet your needs.

Many times, success lies in understanding the details to select the proper sensor. To quickly facilitate an NDA, MaxBotix, provides a two‑way mutual NDA. Please contact your sales rep if you have any questions during this process.

DESIGN TIP If a semi‑custom or custom solution is required, we require an NDA. This allows us to gain a complete understanding of your sensor needs which assists us in making the best recommendations for your application; however, we also strongly encourage NDAs for all high‑volume applications.

B2B projects sometimes include the execution of a contract or statement of work. We like to explore your requirements for such contracts and complete the negotiation process up front. We want to establish mutually beneficial agreements before proceeding to the next phase. This prevents any incompatible terms down the road that could stall the successful execution of your project. Again, please let your sales rep know if you have any questions.

Terms and Conditions of sales are very important to every customer. We recommend that all customers review the MaxBotix Inc Terms and Conditions of Sale.

Phase 3: Product Selection

During this phase, we provide the recommended options for success based on your needs. Additionally, we further discuss any potential specific application needs. Recommendations can include an off‑the‑shelf sensor, a custom or semi‑custom sensor NRE project, or a feasibility study for unknown applications. After product selection takes place, the quoting process begins.

Product Selection

The best way to ensure a successful application is selecting the correct sensor. The thorough discovery process that takes place in Phase 1 & Phase 2 helps us weigh which options are most suited to your application. Several options are available, each having unique advantages.

Standard Sensors

After understanding your application and requirements we will know if an off‑the‑shelf sensor solution will work for you. Our standard sensors are ready to ship which means you can immediately order sensors for testing. Provided the sensor meets all the requirements to make your application successful, we will recommend one of our standard sensors for testing.

One of the tools that we may use during this phase is our Sensor Selection Guide. The guide recommends a number of sensors based on proven applications. This guide can be very helpful during product selection. If you have any questions, please let your sales rep know and they will be glad to help you.

DESIGN TIP Selecting your sensor requires consideration of the sensor’s detection zone beam patterns. Understanding the typical detection zones is a critical part of the application that becomes crucial during testing. For more information on beam patterns, see Reading MaxSonar Beam Patterns article on the News page of our website.

DESIGN TIP If you are familiar with using an oscilloscope and have access to one, selecting one of our MB13## or MB70## series sensors with the Analog Envelope output on Pin 2 can be invaluable during the integration process. The Analog Envelope provides a processed waveform that shows the targets in your environment, giving you an understanding of how the sensor actually sees its surroundings.

Feasibility Study Sensor Specification

The next potential step would be a feasibility and specification study. During this study, MaxBotix takes your application information and conducts rudimentary testing and analysis where required. The goal of the feasibility and specification study is determining the potential for success when using an ultrasonic sensor in your application. Additionally, we collaborate with you on the sensor specifications as defined in an Interface Control Document (ICD) which is used to complete the Non‑Recurring Engineering (NRE) quote discussed later in this article.

Semi‑Custom Sensor

After completing the feasibility study, we consider designing a semi‑custom sensor utilizing our NRE process. A semi‑custom sensor usually features one of our standard products with modification to the firmware. Some of the most common types of semi‑custom sensors are those with a custom trigger distance or triggering timeline to match specific requirements. This option provides you with a rapid cost‑effective development cycle to deliver a sensor that specifically matches your application.

Fully Custom Sensor

The final service option is a fully custom sensor that is developed using our NRE process. A custom sensor is more involved than a semi‑custom sensor. This option also provides a time‑efficient, cost‑effective solution, in which, MaxBotix matches all your hardware and firmware requirements. This may include sensor color, branding requirements or even sensor shape and layout. In most cases, we complete such a development cycle in 3 to 12 weeks, depending on the scope of engineering and testing required.

DESIGN TIP When looking at a sensor solution, you must look at the total cost of ownership. The costs associated with an NRE development cycle many times result in a lower total cost of ownership rather than using a sensor that does not match all the requirements and requires expensive workarounds or in‑field repairs. Additionally, we may be able to reduce your production costs by providing a sensor that interfaces directly with your system vs. requiring you to add additional hardware to make the interface compatible.

DESIGN TIP To help reduce the cost and delay of scope creep on your project, the information review, and verification at the end of the product selection is vital to the process. It is important that you look at all the details, and if you have any questions, let your sales representative know so that we can ensure your solution is complete.

Once an option is selected, MaxBotix provides links and documents to all relevant information for your review. This step is critical because you know your application best. If you have any questions, contact your sales representative. Our mutual goal is to ensure that all of your requirements are included in your solution. Our process requires that we discuss your needs and that you send a written confirmation for your sensor selection.

The Quoting Process

Upon completion of the product selection process, we are able to complete the quoting process. There are several types of quotes that MaxBotix Inc., provides.

- Request for Price (RFP): An RFP is commonly used early during the project. This number helps determine the long‑term feasibility of a project to meet the expectations regarding the sensor’s per unit price.

- MaxBotix believes in having clear prices for our products. As a result, we do not negotiate special pricing for our customers (outside of volume pricing and distributorship agreements). Not offering special pricing serves to reduce our office overhead and results in much lower pricing for our customers. We determine the price of our products by our cost to produce in volume.

- Standard Quote: This quote is for a set quantity with a requested delivery date. For your convenience, you can order up to 100 units directly from our website and receive quantity price breaks.

- Feasibility & NRE Conceptual Bid: A ballpark cost estimate of the sensor project is based on our current knowledge. This quote gives you perspective as to what our expected development costs will be associated with the project.

- Feasibility & NRE Quote

- Feasibility Quote: This quote declares the cost of feasibility testing and development of the ICD for the sensor. The NRE quote can only be completed after the ICD is completed. The feasibility study gives us the information we need to provide a conceptual design and an NRE quote.

- NRE Quote: The development costs of the semi‑custom or custom sensor solution along with any required testing.

- Scheduled Shipments Quote: MaxBotix provides a series of shipments to allow you to receive the best per unit pricing.

With every quote, there is an associated lead time. MaxBotix makes every effort to meet our customer’s expectations regarding delivery. As such, if you have any questions regarding the lead time, please work with your sales representative. We will work with you to collaborate on a delivery timeline solution.

DESIGN TIP To maintain our cost‑effective sensor pricing we are very upfront with our high volume pricing. As a result, you can trust our pricing will be maintained to the best of our ability over the life of your project.

Phase 4: Proof of Concept & Testing

During this phase, we ensure that the sensor used in the application will be successful. An NRE project and feasibility studies begin during this stage when applicable. Once the proof of concept is proven to work, testing increases in scale and a larger quantity of sensors are used to ensure any previously unidentified issues are discovered. The test sample size is typically 1% to 10% of the total quantity being installed. This phase is complete when you issue a written approval that the application is successful as designed.

This phase encompasses three tests to provide a systematic quantification of the sensor in the application.

- Proof of Concept: A simple mock-up to prove the idea works

- Prototype Testing: Testing the proposed final design

- Pilot Lot Testing: Testing the final design in a large batch

This recommended testing sequence is an iterative process where to identify and correct any future issues that may appear in the field ensuring a successful application that can pass the test of time.

Proof of Concept

After choosing a sensor, the building of your initial proof of concept may begin. Ultimately, this provides clarity to any lingering questions and gives you real feedback regarding your application. The proof of concept allows you to put everything together to see how it works. During this process, some changes may be needed to achieve the desired level of performance in nearly all applications.

The proof of concept is often completed with various forms of equipment which may include breadboards, socket microcontrollers, clip leads, and a host of other electronics. The idea is to put together a system in which you can prove that the application and the sensor work as intended.

DESIGN TIP It is best to test the sensor in the end application. The closer you can match the proof of concept to the final application, the less risk of finding unforeseen technical challenges later. For example, if you plan to use three sensors next to each other, test three sensors next to each other. Successful ultrasonic sensor integration is about accommodating all the small details that affect performance.

Refer to our easy-to-use Quick Start Guide to get your sensors up and running.

DESIGN TIP Electrical noise can be one of the most frequent causes of sensors performing different than expected. The best option is to consider installing our MB7961 Power Supply Filter.

Sources of electrical noise can be electric motors and wireless transmitters on the same ground plane as the sensor. Separating the sensor ground plane from such types of devices will greatly reduce electrical noise issues. Acoustic noise can be another source that causes interference. See our MaxSonar Sensor Acoustic Noise Tolerance Test article.

Prototype Testing

Prototype testing takes the proof of concept to the next level as you test the final hardware design for your application. Additionally, this is the place to test the exact environment where you will use the sensor. You should test hardware and firmware that is fully integrated. This prototype testing is critical to making any needed changes prior to pilot lot testing.

All of the design tips listed in the Proof of Concept section may be helpful in this step of testing as well.

Pilot Lot Testing

There is an old carpentry phrase “measure twice, cut once” which definitely applies to integrating ultrasonic sensors into your application. Anything less and you may get unexpected results. That is exactly what pilot testing is about.

You made it through all the major design specifications, technical challenges, and environmental variables which were identified and accounted for in your development process. You have a working solution. Now, you are expanding your testing sample size and verifying the final deployment of your design prior to release. The goal of pilot testing is to test and verify that the application will be successful during the final rollout. This is the time to discover and correct any details that may have been missed in the prototype and proof of concept testing due to the small size of test samples.

DESIGN TIP If you are experiencing any issues in getting the sensor to work in your application, see the MaxSonar Troubleshooting Guide for more information. It will help with the initial phase of verifying the sensor operation in your application.

Contact Sales Support if you are unable to troubleshoot the issue. Our technical team will help troubleshoot the issue to get you running quickly. Before you call, be sure to have detailed application information. If you can provide data capture files with the unprocessed data from the sensor, it may give us insight into the issue you are experiencing.

If testing is not initially successful, it does not mean game over. It simply means we are one step closer to your final design. Our team will continue to work with you to evaluate a solution to the new challenge. At this point, we are often able to collaborate to find a successful solution.

Phase 5: Production Planning

This is a critical phase of the overall success of the project as we collaborate and finalize the desired deliveries. MaxBotix audits its lead times to ensure the most current information is used during this process. We, do our best to meet the shipping demands of each customer while communicating the feasibility to meet their requirements. Once we agree to the production plan, a scheduled quote is issued and the high‑volume purchase order is submitted.

Finalizing Your Production Details

A tentative schedule based on your production requirements is put together. We collaborate on the delivery dates to meet your needs. During this process, we verify that our supply line will meet your requirements and delivery schedule. We discuss any delivery discrepancies that may exist. We also discuss the payment schedule to ensure your shipments are able to arrive on time.

You can expect that we will work together on the quote until we mutually agree on the production plan and schedule. Once there is mutual agreement on the production schedule, a signed quote and/or PO, and a down payment are received, Phase 6: Full Production starts. Additional payments may be required when the first deliveries are expected on a compressed timeline.

DESIGN TIP Ask one of our sales representatives about our product accessories or contract-manufacturing services like adding wires, connectors, or even mounting the sensor in the final assembly.

Your Competitive Advantage

We provide cost-effective, high-performance sensor solutions to help you have the competitive advantage you need to achieve the best pricing that creates a win-win for everyone. As your sensor supplier, we have achieved this in several unique ways.

- Secure & Reliable Supply Chain. As a start‑to‑finish manufacturing company, we understand the need for exceptional products. We choose to do business with vendors that provide us with quality products and services so you can rely on us for your sensor needs.

- High Volume & Scalable Production. We easily support deliveries of over 10,000 units per week.

- Prepayment Policy. Prepayment benefits us and our customer base because MaxBotix does not pass along the additional costs of payment tracking, delayed payments, late payments, or non-payment into the pricing structure. Prompt payment with our payment policy will get your order processed. The lead time countdown for your order starts once the payment is received. Give your finance department a heads up, so they can complete this process quickly. This ensures we are able to start manufacturing your solution in the desired timeline. If there are any questions regarding this payment policy, one of our friendly sales staff will be glad to help.

- Designs that Last. Robust sensor hardware designs that hold up to the test of time and rugged environments with MTBFs of over 200,000+ hours. See the MaxSonar Reliability Demonstration article.

DESIGN TIP Our pricing structure is stable and the price we quote you is the pricing that remains throughout your project. However, pricing may increase if the scope of the project changes.

Phase 6: Full Deployment & Production

At this phase, our order processing department issues the invoice for the required payment. Vendor lead times are confirmed with MaxBotix Inc., product shipment schedules. We then start the production of the units. Required payment is received before shipments are started and/or released from our manufacturing facility. Phase 5 and 6 are repeated as needed over the life of the project.

Speak to your MaxBotix sales representative with any questions regarding down payment. Lead times are calculated from the date the down payment is received.

With the order submitted to production, purchasing schedules all the required orders with our vendors. These lead times are verified prior to sending the quote, however, the occasional adjustment to lead times may be required as a result of delays in order placement. We will discuss any such changes to lead times with you should the issue arise.

Each shipment is produced according to the schedule ensuring your requirements and expectations are met. The payment for each individual shipment is typically scheduled 1 to 3 weeks prior to the shipping date. This prevents unforeseen processing delays from impeding your shipment.

Advantages of MaxBotix Manufacturing

We are a high volume manufacturer and our highest priority is to meet your delivery requirements and expectations. When MaxBotix manufactures your sensors, you will experience these advantages.

- High Volume Manufacturing Process Controls. We are a process-based manufacturer which ensures our customers receive the same sensor today as a year from now. We have strict compliance and QA policies, inspection, and 100% testing on all sensors, leaving our facility. You can have full confidence in the sensors that arrive at your facility.

- Secure & Reliable Supply Chain. As a start‑to‑finish manufacturing company, we understand the need for exceptional products. We choose to do business with vendors that provide us with quality products and services so you can rely on us for your sensor needs.

- In Stock. Quick Delivery. Our standard products are in stock for quick delivery. Prompt payment will get your order processed quickly. It is important that your finance department is aware of our prepayment policy so they can process your purchase order and submit payment. Once payment is received, we start manufacturing the solution that meets your project’s requirements.

- Delivery of Semi-Custom Solutions. We use as many standard components as possible for all sensor designs. Couple that with our reliable vendor supply chain and we will do everything possible to meet all manufacturing timelines.

- Flexible Scheduling. We will work with you for scheduling projects where the sensor solution was needed yesterday.

- Contract Manufacturing Services. We offer contract manufacturing services like adding wires, connectors, or even mounting the sensor in the final assembly. Ask one of our MaxBotix Inc., sales representatives for more information regarding such services.

Phase 7: Feedback Evaluation

Now is the time when you are able to help us improve your experience in the future. We want to know how everything went. What was good, where can we improve, and how did our products and service accomplish your goals.

Our culture is an environment of continuous improvement. We use your feedback to evaluate our processes and procedures. This is done by taking a look at a few basic questions to help us evaluate your experience.

How well does MaxBotix Inc, meet your expectations?

Customers have set expectations. Customers rightfully expect excellent customer service and high-quality products. Beyond that, each customer has specific expectations for succeeding in their production cycle. The first question we ask tries to nail down these expectations. When we understand your expectations we can work to better align our services and processes to meet and surpass your expectations. Our goal is to leave you wanting to continue our business relationship with your current and future applications. We appreciate your feedback, both positive and negative because it allows us to improve your customer experience in the future.

How are we doing and what is going well?

If the products are excellent, customers generally continue to patronize a company even when their services fall short. This leads to the second question, “What are we doing well?” Our goal is to provide you with quality products, and an excellent customer experience.

How do our products perform in your application?

The reason you came to MaxBotix Inc., was because you needed a sensor. We want to hear about how our sensors are performing in your application.

Where can we improve your experience?

There is always room for improvement. Our final question provides you with an opportunity to comment on anything big or small that you feel we can do better.

DESIGN TIP MaxBotix has a formal step in our process for feedback, and we welcome your feedback at any time during the design cycle. If there is a question or concern, positive or negative, please contact a MaxBotix sales representative so we can discuss it and improve our process if necessary.

Phase 8: Partnership & Future Projects

We want to continue working with you on future projects where our products and services can help make you be successful. Additionally, we want to hear about other businesses that you feel can benefit from our services.

MaxBotix is committed to the success of our customers. We hope that your first experience solidifies your desire to partner with us on future projects. MaxBotix offers a variety of services to help you achieve success.

Why does MaxBotix Inc partner?

We believe that the same way one chooses a friend should be reflected in the way they select a product for their application. We see every customer as a partner. You need to be able to trust the product and the supplier. You also need to know that the supplier will stand by you. You can expect to be treated well before, during, and after the purchasing process. MaxBotix takes ownership of nurturing relationships with the hope they will last a lifetime.

Customer Satisfaction

Customer success and satisfaction is our number one priority. A customer came to us with a unique problem. The customer needed a sensor for collision avoidance on their robot to prevent damage to the robot and surrounding environment. We collaborated on the project including a thorough review of the requirements. We determined that an off-the-shelf sensor solution would work for proof-of-concept and prototyping. They successfully integrated this sensor into their design providing the needed detection. Once the proof-of-concept was completed, we customized the sensor which required a specific color to match the production requirements for the robot design. MaxBotix Inc. has the ability to match color requirements which allowed our customer to deliver a robot with a professional appearance. Once this phase of the design was completed, they rolled into full production with a typical shipment size of 10,000 units that has been running successfully for several years now.

MaxBotix Inc., Services Available for your Success

MaxBotix Inc. offers a number of services to help you through any challenges you may run across in your various applications. Some of the most common services are:

- Application‑specific sensors

- R&D feasibility studies and sensor specification

- Engineering semi‑custom sensors

- Engineering fully custom sensors

- Product accessories

- Turn-key manufacturing services

Ask your sales representative if you are interested in any of the above services.

Applications We Support

Ultrasonic sensor technology is used in many applications. These are some of the more common applications:

- Automated Store Displays

- Booths & Kiosks

- Car Detection

- Dimensioning & Positioning

- Freight Management Systems

- Liquid Level Control

- Lithium Battery Applications

- Long Range Object Detection

- Mobile Robotics

- Non‑Contact Detection

- Parking Garages

- People Detection

- Proximity Detection

- Remote Monitoring Stations

- Shipping Systems

- Solar Powered Applications

- Tank Level Measurement

- Tide/Water Level Monitoring

- Trash Level Measurement

- Security Systems

We look forward to working with you on future projects. We want to continue to earn your business through partnership. If you have any questions about our design cycle process, contact your MaxBotix sales representative or use the ASK A QUESTION button at the top of this page. Our goal is to build lasting relationships and partnerships for a win-win for our customers and for MaxBotix Inc.